Technical foamed plastics:

Our raw materials

ISOWA – The better solution.

Technical foamed plastics:

Our raw materials

ISOWA – The better solution.

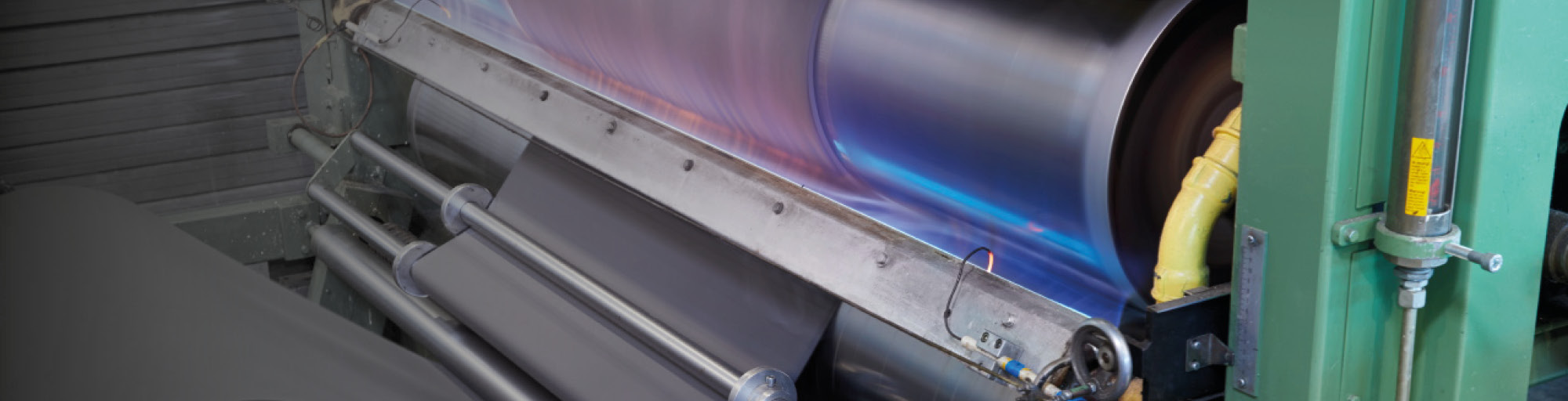

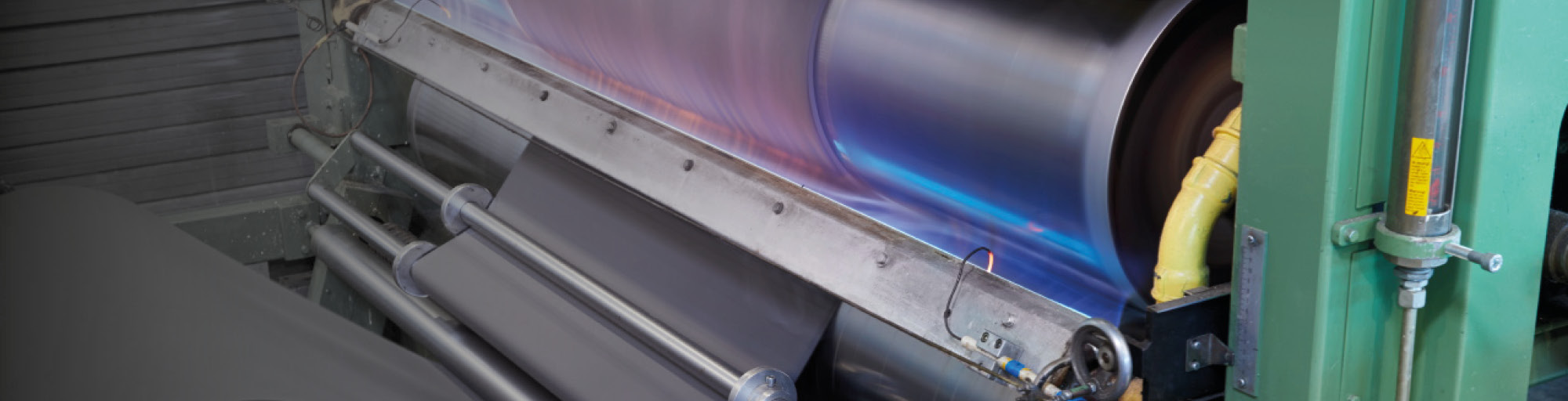

With over 40 years of success, ISOWA has evolved into a specialist in processing, machining, and combining all types of technical foam plastics. We also act as a bridge between the innovations of semi-finished product manufacturers and our customers, using our extensive expertise to offer the best possible advice. Our deep understanding of the functions, benefits, and limitations of various materials allows us to tackle even the most complex challenges – such as adhesive components that need to stick to dirty surfaces. In these cases, too, we have the right solution for you. Don’t hesitate to reach out or learn more about our manufacturing processes.

Naturally, we also accommodate any specific material requests from our customers, and we always keep essential raw materials in stock.